Power supply design and verification test solutions

The RPS-5000 ensures stability and performance in power supply design for appliances, lighting, transformers, and more, meeting strict quality and safety standards.

01.

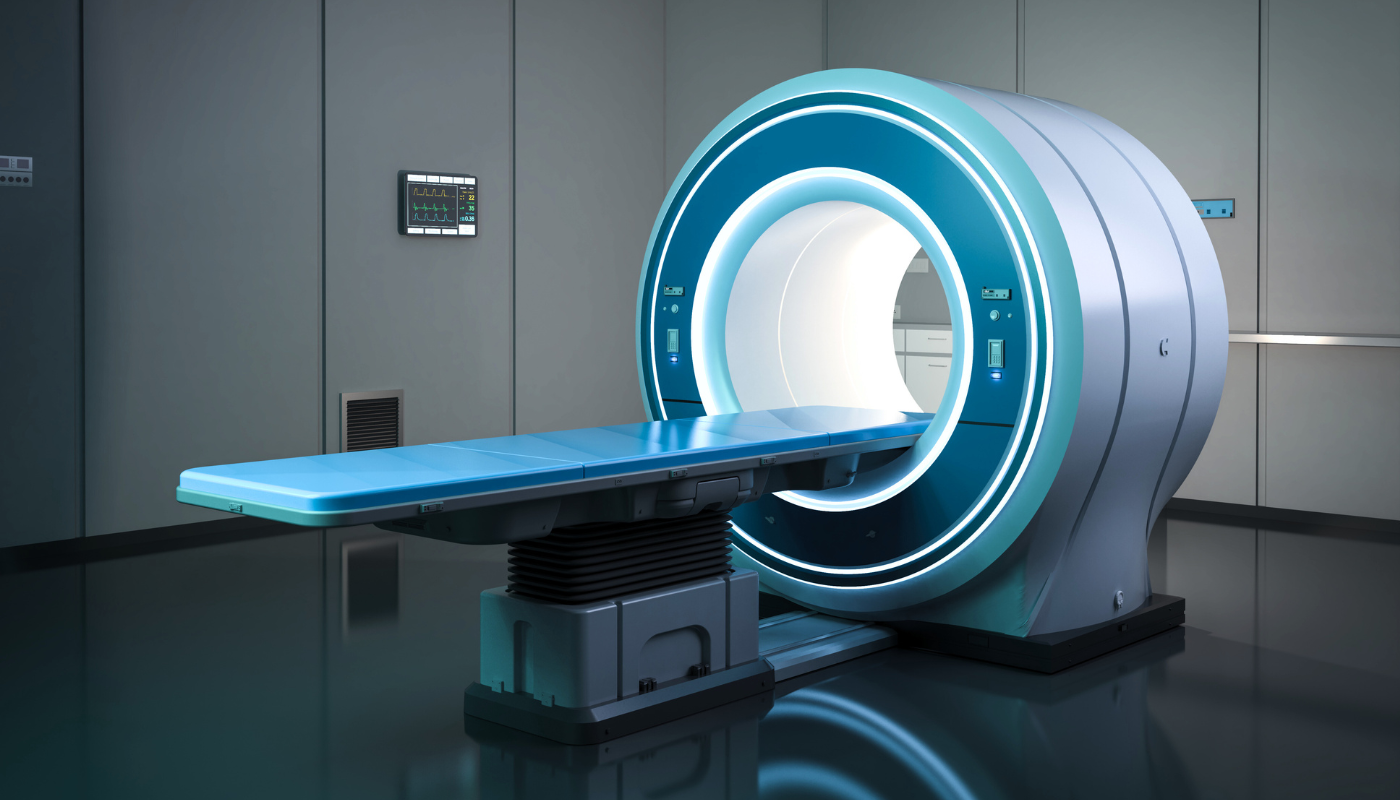

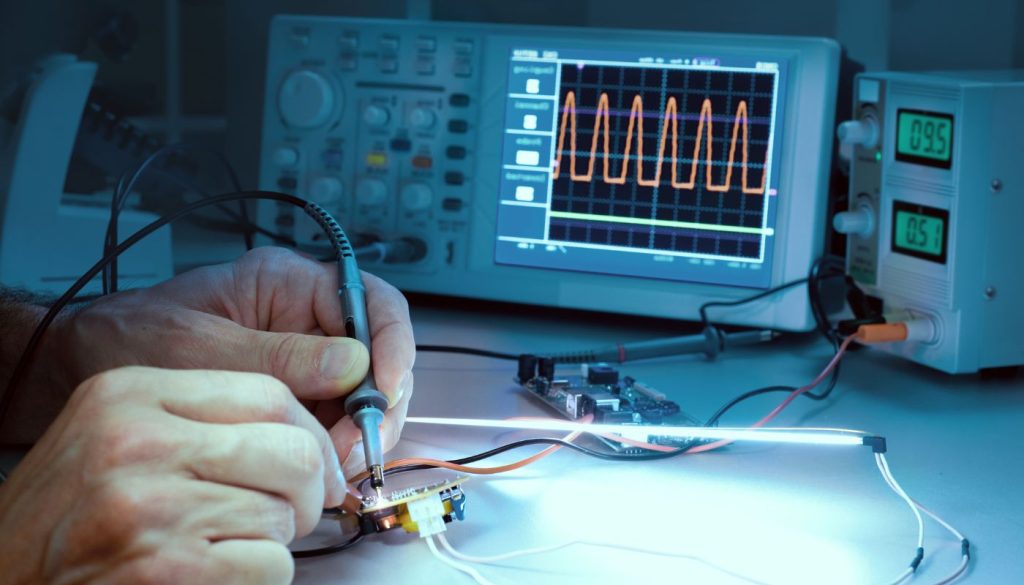

State-of-the-art test equipment for design and verification

The RPS-5000 provides advanced testing capabilities for AC/DC product design and verification, ensuring quality, safety, and reliability throughout the product lifecycle. Its programmable power supply simulates real-world conditions for testing industrial, lighting, medical, and consumer power systems.

02.

Testing AC and DC fast chargers

The RPS-5000 delivers versatile AC/DC power solutions for testing and verification across industries. It ensures compliance with regulatory standards by accurately measuring power factor, harmonic distortion, voltage regulation, and transient response.

Non-regenerative applications:

- Transformer, generator, inductor testing

- Industrial lighting test system

- Consumer “white goods” and electrical appliances

- Circuit breaker test system

Renewable Energy Applications:

- AC motor testing (regenerative power supply)

- Aging tests (regenerative load)

- Battery charge and discharge tests (DC mode)

Learn about Model G

Model G, experience superior power testing performance! Whether it is new energy, electric vehicles, or complex industrial applications, Model G can provide you with accurate, stable, and reliable testing solutions. Contact us now for more information and to inject new impetus into your R&D and

03.

Seamless transition from R&D to production

As the product life cycle evolves, our AC/DC power supplies and loads can easily transition from engineering development to production use. Stable voltage and frequency are necessary to reduce product scrapping due to poor factory power conditions. Our products provide stable output while input voltage or frequency may vary +/-10%. This ensures that the product will not malfunction due to the factory's low voltage wiring. Because our remote control programming syntax is standardized across platforms, test software developed during product design can also be easily transferred to meet production test requirements.

04

Testing EVSE and car chargers

Our EMC power line emissions and immunity compliance test systems are designed to provide accurate and reliable testing of a variety of grid-connected equipment, including renewable energy systems, home appliances, industrial equipment and more. These systems are critical for manufacturers, testing laboratories and certification bodies seeking to ensure that their products comply with the latest EMC standards.

Together, we make a difference.

In the testing of new energy equipment, stability and reliability are crucial. Infilin relies on the design verification of the world's leading brands and the quality assurance of world-class smart manufacturing plants to provide you with test power solutions that can stand the test of time. Join us to help you meet stringent product performance and compliance requirements with the highest quality power support, and drive a sustainable production future!