In today’s digital and electrified world, ensuring that electronic and electrical equipment can withstand disturbances and continue to function reliably is not just a luxury—it’s a regulatory necessity. As modern power systems increasingly rely on sensitive semiconductors, bidirectional inverters, programmable controllers, and renewable integration, the electromagnetic environment becomes more complex and susceptible to disturbances. This is where electromagnetic compatibility (EMC) standards come into play. One of the most critical among these is IEC 61000-4-11, a standard designed to test equipment’s immunity to voltage dips, short interruptions, and voltage variations on the AC power input.

This section provides a comprehensive overview of IEC 61000-4-11, its position within the IEC 61000 standard family, and its importance for global manufacturers, developers, and testing engineers.

What Is EMC and Why Does It Matters?

Electromagnetic Compatibility (EMC) refers to a device’s ability to function as intended in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment. The ultimate goal is coexistence: equipment must resist interference from external sources and also limit the emission of electromagnetic noise that may affect other devices.

Key requirements include:

- Emissions control: Limiting the amount of electromagnetic energy released by the equipment.

- Immunity compliance: Withstanding electromagnetic disturbances like voltage sags and surges.

Failing EMC compliance can result in:

- Malfunction of devices such as EV chargers, grid-connected inverters, or industrial controllers.

- Violations of regulatory law (in the EU, USA, China, etc.).

- Increased warranty claims and recalls.

The IEC 61000 Series – The Foundation of EMC Standards

The IEC 61000 series, issued by the International Electrotechnical Commission (IEC), is the most widely recognized framework for EMC testing. It defines both emission and immunity standards for electrical and electronic equipment. It is divided into parts, each targeting a different type of EMC issue:

| Part | Focus Area |

| IEC 61000-4-2 | Electrostatic discharge (ESD) immunity |

| IEC 61000-4-3 | Radiated RF electromagnetic fields |

| IEC 61000-4-4 | Electrical fast transients (EFT) |

| IEC 61000-4-5 | Surge immunity |

| IEC 61000-4-6 | Conducted disturbances |

| IEC 61000-4-11 | Voltage dips, short interruptions, and voltage variations |

Scope of IEC 61000-4-11: Immunity Testing for AC Input

IEC 61000-4-11 specifically addresses low-frequency disturbances in the AC power supply, which can cause critical failures if not properly mitigated. The standard focuses on equipment with input current up to 16 A per phase, including:

- Office equipment

- EV chargers and supply equipment (EVSE)

- Power conversion systems

- Renewable energy inverters

- UPS and data center backup systems

- Laboratory-grade programmable power supplies

This makes the standard particularly vital for companies producing devices used in smart grids, EV infrastructure, renewable energy testing, and precision industrial automation.

Real-World Power Disturbances Covered by IEC 61000-4-11

| Disturbance Type | Description | Typical Cause |

| Voltage Dip | Voltage sags range from 0–80%, corresponding to durations from 0.5 to 250 cycles. Refer to the dips table below for detailed mappings. | Motor startups, grid faults, large load switching |

| Short Interruption | Temporary total loss of voltage | Utility grid outage, internal breaker trip |

| Voltage Variation | Gradual increase or decrease in supply voltage | Load changes, poor regulation, under/over-voltage conditions |

The goal of the IEC 61000-4-11 test is to simulate these conditions and evaluate the equipment’s immunity.

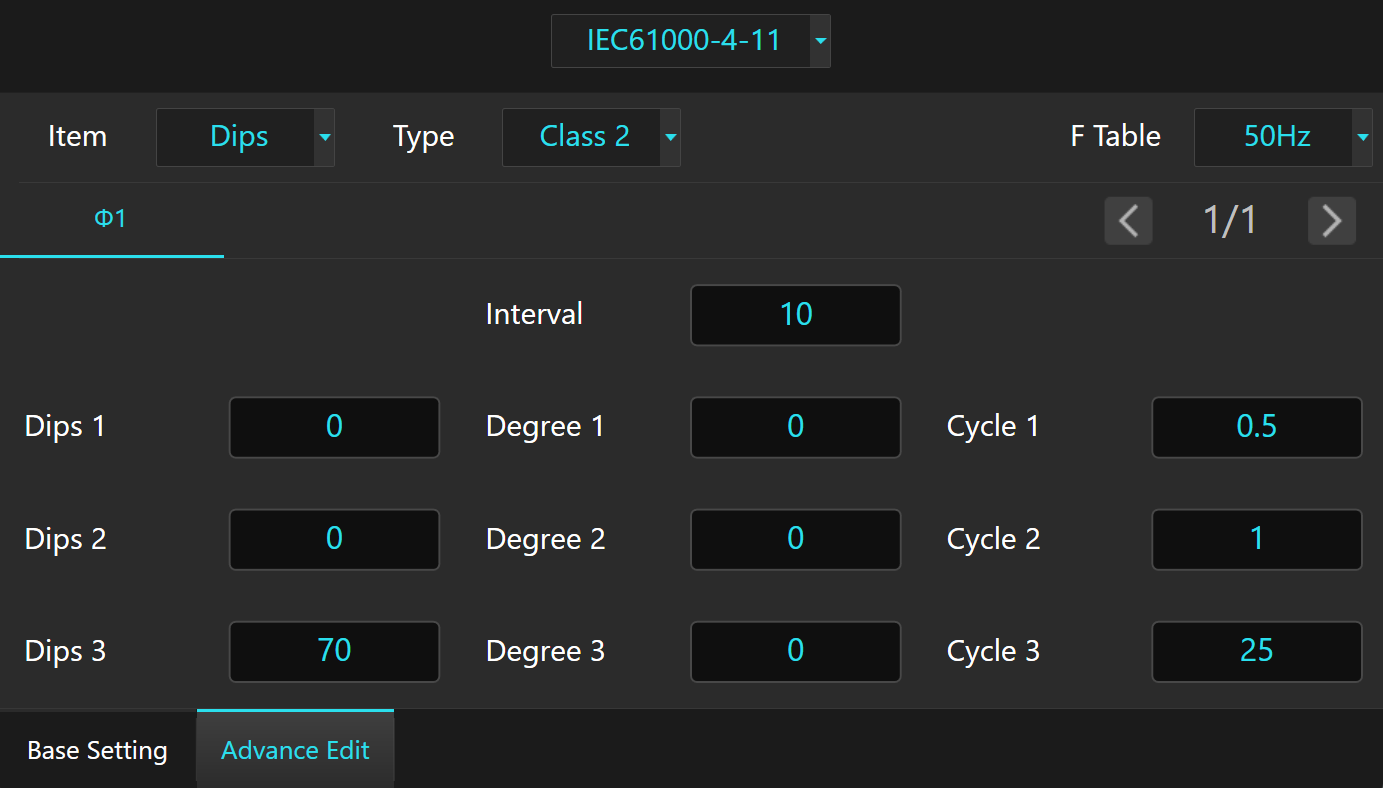

Dips

As voltage changes occur suddenly, voltage dip immunity tests must be conducted sequentially with a minimum interval of 10 seconds between two tests. Each test level should be performed in sequence for a total of 3 tests.

Table: Preferred Test Levels and Durations for Voltage Dip Testing

| Level | Voltage Dip Test Levels and Durations (ts) (50Hz/60Hz) | ||||

| 1 | To be carried out sequentially according to equipment requirements | ||||

| 2 | 0% voltage dip, duration: 0.5 cycle | 0% voltage dip, duration: 1 cycle | 70% voltage dip, duration: 25 cycle | ||

| 3 | 0% voltage dip, duration: 0.5 cycle | 0% voltage dip, duration: 1 cycle | 40% voltage dip, duration: 10 cycle | 70% voltage dip, duration: 25 cycle | 80% voltage dip, duration: 250 cycle |

Why Manufacturers Must Comply

Compliance with IEC 61000-4-11 is not optional in most regulated markets. Manufacturers that want to sell globally must show that their equipment can:

- Withstand sudden voltage anomalies.

- Restart cleanly after a voltage interruption.

- Maintain safe and reliable operation without data corruption, loss of function, or user danger.

Failure to comply can result in:

- Delayed product launches.

- Rejected certification applications (CE, FCC, CCC, etc.).

- Liability risks in safety-critical environments.

For companies designing EV charging infrastructure or grid-tied renewable energy systems, compliance is not just for safety but a pathway to market access.

EMC Compliance and IEC 61000-4-11 in Global Markets

| Region | Regulatory Authority | Related EMC Requirements |

| EU | CE Marking (EN 61000 equivalents) | Mandatory for all electronic devices |

| USA | FCC, UL (incl. UL 1741) | Required for inverters, UPS, and more |

| China | GB/T standards (adapted from IEC) | GB/T 17626.11 = IEC 61000-4-11 |

| Taiwan | BSMI, CNS standards | CNS 13438 + CNS 14843 |

| Japan | VCCI compliance | Often based on CISPR + IEC specs |

Using equipment like the RPS-5000 series from InfiniPower, companies can easily simulate and test compliance without needing a third-party lab in the early R&D phase.

Summary: The Critical Role of IEC 61000-4-11 in Product Safety and Performance

IEC 61000-4-11 is not just a test method, but a core pillar in designing and validating resilient equipment. Whether you are building EV infrastructure or data center UPS systems, understanding how your device responds to grid disturbances is crucial.

The RPS-5000 regenerative AC/DC simulator provides integrated support for this standard, allowing engineers to:

- Simulate voltage dips and interruptions.

- Monitor waveform response in real-time.

- Ensure readiness for international certifications.

References

- International Electrotechnical Commission. (2017). IEC 61000-4-11: Electromagnetic compatibility (EMC) – Part 4-11: Testing and measurement techniques – Voltage dips, short interruptions and voltage variations immunity tests. https://webstore.iec.ch/publication/3112

- International Electrotechnical Commission. (2021). IEC 61000 series – Electromagnetic compatibility standards overview. https://www.iec.ch/standards-devices/emc

- UL Standards. (2022). UL 1741: Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources. https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=29042

- IEEE Standards Association. (2018). IEEE 1547: Standard for Interconnection and Interoperability of Distributed Energy Resources. https://standards.ieee.org/standard/1547-2018.html

- China National Standardization Administration. (2015). GB/T 17626.11-2008 (equivalent to IEC 61000-4-11). http://openstd.samr.gov.cn/

- Bureau of Standards, Metrology and Inspection (BSMI). (2023). CNS 13438 and CNS 14843 for electromagnetic compatibility in Taiwan. https://www.bsmi.gov.tw/

- InfiniPower. (2024). RPS-5000 Datasheet V1.0: Regenerative AC/DC Grid Simulator. https://www.infinipowertech.com/products/rps-5000