1. What is Power Testing?

Power testing involves using various testing equipment and techniques to assess and verify the performance, safety, stability, and compliance of electrical equipment. This process spans the stages of product development, production, installation, and maintenance to ensure reliable operation in real-world environments. As electrical equipment applications continue to expand—from power transformers and distribution systems to household appliances and EV charging systems—the importance of power testing grows significantly.

1.1 Definition and Importance of Power Testing

Power testing encompasses a wide range of evaluations, from basic electrical parameter measurements (e.g., voltage, current) to advanced safety tests (e.g., insulation withstand, overload protection). The goal is to ensure that electrical equipment operates without performance instability or safety risks, ensuring reliable operation in practical applications. With the trend toward efficient, intelligent, and renewable-energy-powered electrical equipment, power testing is becoming increasingly vital.

For example:

- Transformers require performance verification under varying loads and temperatures.

- Household appliances undergo testing to prevent electrical fires or shocks.

- EV charging systems rely on accurate and comprehensive testing to ensure charging safety and user experience.

Power testing is a necessary step in ensuring compliance with international standards and regulations (e.g., UL, IEC, GB). Without rigorous testing, equipment may exhibit instability, susceptibility to interference, or severe safety hazards, emphasizing its critical role in modern industries.

1.2 Objectives of Power Testing

The primary objectives of power testing are to ensure stable equipment operation in complex, dynamic environments and to meet relevant technical and safety standards. Key goals include:

- Ensuring Equipment Safety:

- Safety is paramount. Tests like withstand voltage, leakage current, and insulation ensure that equipment doesn’t cause electrical fires, short circuits, or electric shocks under extreme conditions.

- Guaranteeing Equipment Reliability:

- Reliability ensures long-term stable operation without failure. For instance, distribution equipment must maintain stability under high-load conditions, avoiding temperature-induced faults.

- Compliance with Standards:

- Power equipment must meet regional standards like CE (EU), UL (North America), and CCC (China).

- Evaluating Performance Under Various Conditions:

- Testing includes simulations of extreme temperatures, humidity, and load fluctuations to ensure consistent performance.

1.3 Application in Production

Power testing is integral across the production lifecycle, encompassing three critical stages:

- Design Phase: During this phase, engineers conduct rigorous simulations and prototype evaluations to verify design feasibility and performance against predefined specifications. Key aspects include stress testing and ensuring alignment with regulatory standards.

- Production Phase: This stage employs automated and batch-testing equipment to ensure that every manufactured product meets stringent electrical performance and safety standards. Advanced analytics are often utilized to detect anomalies and improve process efficiency.

- Delivery and Installation Phase: Final testing involves verifying the equipment’s ability to function seamlessly in real-world conditions. This includes on-site evaluations to ensure stability, compliance, and user safety under operational loads.

By integrating power testing at each of these stages, manufacturers not only uphold high standards of product quality and safety but also enhance competitiveness in global markets through compliance with international certifications.

2. Core Concepts and Parameters in Power Testing

2.1 Key Parameters

Power testing involves the meticulous evaluation of a range of critical parameters that determine the performance, safety, and reliability of electrical equipment. These parameters are not only foundational to understanding equipment behavior but also critical for ensuring compliance with industry standards and operational stability. Below are the expanded details of common parameters:

- Voltage:

- Definition: Voltage represents the potential difference that drives current through a circuit, a fundamental measure in electrical systems.

- Measurement Tools: Precision instruments such as digital multimeters and voltage probes are used for accurate readings.

- Standards Compliance: Tests adhere to regulations like IEC 61000-4-2, which specify thresholds for electrostatic discharge and voltage stability.

- Application Insight: Voltage testing ensures compatibility across varying load conditions and is essential in devices like power transformers and household appliances.

- Current:

- Definition: Current quantifies the flow of electric charge, reflecting the operational efficiency of a system.

- Evaluation Metrics: Continuous monitoring with high-accuracy ammeters or current transformers provides insights into system performance under dynamic conditions.

- Standards Alignment: Ensures adherence to safety norms to prevent overcurrent scenarios that may damage components or compromise safety.

- Impedance:

- Definition: Impedance combines resistance and reactance, offering a holistic measure of opposition to current flow in AC systems.

- Advanced Measurement: Using impedance analyzers, engineers evaluate frequency-dependent changes to optimize circuit design and signal integrity.

- Practical Use: Critical in evaluating the performance of filters and ensuring signal stability in communication and power circuits.

- Power Factor:

- Definition: A dimensionless ratio of active power to apparent power, indicating energy conversion efficiency.

- Operational Impact: Higher power factors signify efficient power usage, reducing losses in industrial systems.

- Tools: Power factor meters accurately measure phase differences between voltage and current, enabling corrective actions.

- Frequency and Waveform Analysis:

- Frequency: Measured in hertz (Hz), it reveals the consistency of power delivery, especially in systems like inverters and generators.

- Waveform Distortion: Analyzing deviations from ideal sinusoidal waves identifies issues like harmonics, which affect energy quality and efficiency.

- Advanced Equipment: Oscilloscopes and spectrum analyzers enable detailed visualizations, assisting in fine-tuning equipment performance.

2.2 Tools and Techniques

Modern power testing leverages sophisticated instruments and methodologies to achieve precision and reliability:

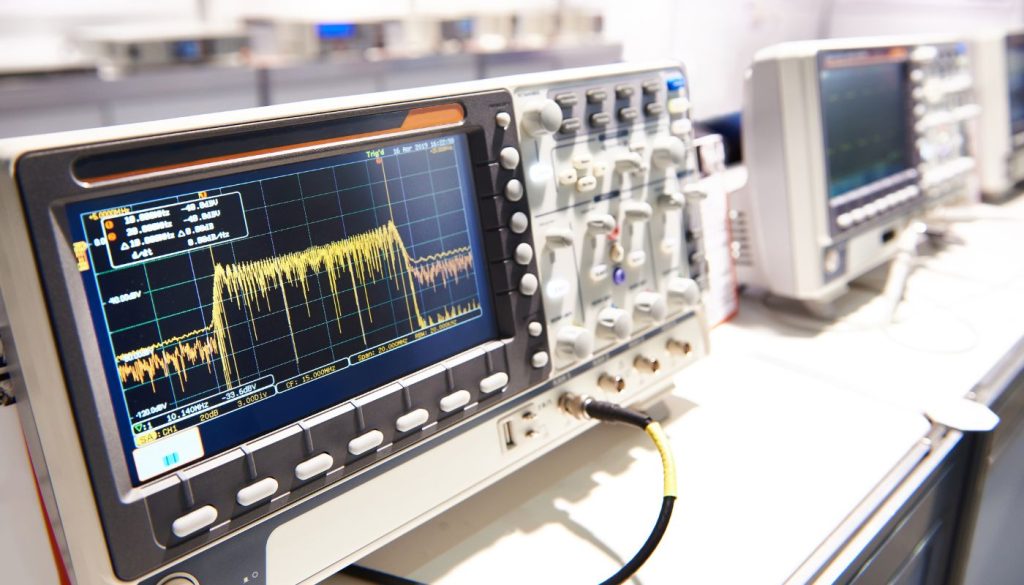

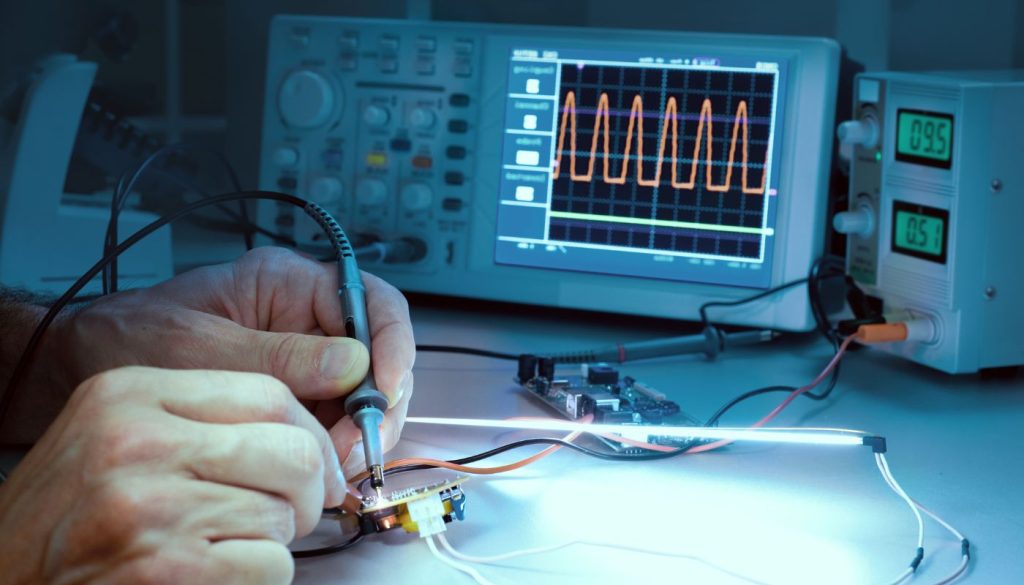

- Oscilloscopes:

- Used for real-time waveform visualization.

- Ideal for detecting transient anomalies and noise in high-frequency applications.

- Frequency Counters:

- Provide accurate frequency measurements critical for devices operating across varying cycles.

- Commonly applied in grid synchronization and high-speed communication systems.

- Impedance Analyzers:

- Evaluate the frequency-dependent behavior of circuit components.

- Essential for ensuring compatibility and optimizing performance in RF and microwave systems.

By employing these tools and focusing on precise measurements, power testing establishes a robust foundation for operational excellence, safety, and regulatory adherence.

3. Types of Power Testing Equipment

3.1 Common Tools

- Electronic Load:

- Functionality: Simulates various load conditions to assess the performance, stability, and efficiency of batteries, power supplies, and inverters. Ideal for evaluating dynamic response and thermal characteristics.

- Applications: Widely used in testing EV batteries, renewable energy systems, and industrial power supplies.

- Advanced Features: Programmable control, dynamic load profiling, and regenerative load capabilities to enhance energy efficiency during testing.

- Power Analyzer:

- Functionality: Precisely measures electrical parameters such as voltage, current, power factor, and efficiency under real-world operating conditions.

- Applications: Essential in R&D and production for analyzing energy conversion efficiency in motors, inverters, and power electronics.

- Advanced Features: Real-time harmonic analysis, multi-channel input for simultaneous testing, and data logging for comprehensive evaluation.

- Oscilloscope:

- Functionality: Captures and analyzes high-frequency signals, enabling engineers to visualize and diagnose transient events and signal integrity issues.

- Applications: Crucial for debugging power supplies, RF circuits, and high-speed communication devices.

- Advanced Features: High sampling rates, deep memory, and automated analysis of complex waveforms such as PWM signals.

- DC Power Supply:

- Functionality: Provides a stable and adjustable power source for testing circuits, components, and systems under controlled voltage and current conditions.

- Applications: Extensively used in prototyping, reliability testing, and validating the performance of electronic devices.

- Advanced Features: Programmable outputs, precision current limiting, and built-in monitoring of load parameters.

- Power Quality Analyzer:

- Functionality: Detects and evaluates voltage fluctuations, harmonic distortion, and power interruptions to ensure compliance with grid standards.

- Applications: Key in testing industrial equipment, renewable energy systems, and utility power quality.

- Advanced Features: Long-term monitoring, transient capture, and integration with SCADA systems for enhanced diagnostics.

3.2 Selection Factors

- Testing Objectives: Select equipment tailored to specific tasks, such as insulation testers for withstand voltage tests or spectrum analyzers for EMI diagnostics.

- Environment Considerations: For fieldwork, prioritize portable, rugged devices with battery operation; for production, focus on automated systems with high throughput.

- Future Scalability: Opt for modular systems that allow upgrades to accommodate evolving testing needs.

3.3 Calibration and Maintenance

- Calibration Best Practices: Follow manufacturer-recommended schedules, typically annual or semi-annual, depending on usage intensity. Calibration ensures traceability to national or international standards, maintaining precision and reliability.

- Preventative Maintenance: Regularly inspect for wear and tear, clean connectors, and update firmware to address known issues and enhance device performance.

- Storage Recommendations: Store in controlled environments to protect sensitive electronics from temperature extremes, humidity, and dust, prolonging equipment lifespan.

4. Common Types of Power Testing

4.1 Power Testing

- Objective: Evaluate performance under different loads and standards like Energy Star.

- Steps: Connect equipment, calibrate, increase load incrementally, and analyze results.

- Applications: EV charging systems, household appliances.

4.2 Withstand Voltage Testing

- Objective: Test insulation under high voltage.

- Steps: Gradually increase voltage, observe current, and record data.

- Applications: Transformers, industrial motors.

4.3 Insulation Testing

- Objective: Assess material integrity.

- Steps: Apply voltage, record resistance, and analyze changes.

- Applications: Generators, cables.

4.4 Short Circuit Testing

- Objective: Evaluate response to faults.

- Steps: Simulate short circuits and observe protection mechanisms.

- Applications: Transformers, switchgear.

5. Industry-Specific Applications

5.1 Industrial Power Equipment

Testing focuses on high voltage, insulation, and short-circuit protection, adhering to standards like IEC 60076.

5.2 EV Chargers and Energy Storage

Tests include communication protocols, insulation monitoring, and BMS performance.

5.3 Renewable Energy Systems

- Wind Turbines: Power quality testing under varying wind conditions.

- Solar Inverters: Efficiency testing with simulated sunlight conditions.

Standards You Need to Know

| Testing Standard/Certification | Applicable Field | Main Testing Items | Detailed Requirements | Notes |

|---|---|---|---|---|

| IEC 61000 Series | Electromagnetic Compatibility (EMC) | Radiated emissions, conducted emissions, ESD immunity, fast transient immunity, surge immunity, power frequency magnetic field immunity | Covers comprehensive requirements from device to system testing, ensuring sufficient interference resistance in various electromagnetic environments. | Commonly used in industrial control equipment, household appliances, communication devices, etc. |

| IEC 61557 Series | Power System Safety Testing | Insulation resistance testing, grounding resistance testing, withstand voltage testing, leakage current testing, loop impedance testing, RCD protection testing | Focused on electrical insulation performance and safety protection in high-voltage, humid, and complex grid conditions. | Primarily applied in distribution systems, industrial electrical equipment, and factory setups. |

| IEC 62109 Series | Photovoltaic Systems and Inverters | Withstand voltage testing, insulation resistance testing, continuity testing, overload protection testing, temperature rise testing | Specifically addresses safety performance for photovoltaic inverters and solar power systems under high temperatures and humidity. | Dedicated to photovoltaic and renewable energy fields. |

| IEC 61851 Series | Electric Vehicle Charging Systems | Charging safety testing, communication protocol testing, insulation performance testing, overcurrent protection testing | Covers energy transfer, insulation monitoring, temperature monitoring, protection functions, and communication protocols (e.g., OCPP). | Mandatory for EV charging system applications. |

| UL 508 | Industrial Control Equipment | Insulation testing, withstand voltage testing, short circuit protection testing, continuity testing | Ensures device safety under high load conditions, typically more stringent than household equipment. | Applicable to industrial tools, control panels, automation systems in North America. |

| UL 1741 | Power Inverters and Distributed Energy Systems | Insulation performance testing, power conversion efficiency testing, grid safety testing | Evaluates safety of inverters and distributed energy systems, including fault and islanding effect protection during grid operation. | Required certification for photovoltaic and energy storage systems in North America. |

| UL 2231 | Electric Vehicle Safety Standards | Charging safety testing, leakage protection testing, short circuit protection testing | Focused on EV charging safety, ensuring electrical stability and insulation system reliability to prevent electric shocks or leakage accidents. | Works in tandem with IEC 61851, especially for North American markets. |

| China CCC Certification (GB Standards) | Household Appliances, Industrial Equipment, Power Tools | Electrical safety testing, EMC testing, environmental adaptability testing | Mandatory certification for electrical equipment entering the Chinese market, encompassing performance, EMC, and environmental resilience. | Required for the Chinese market. |

| CE Certification | Household Appliances, Industrial Equipment, Medical Devices | Electrical safety testing (LVD Directive), EMC testing, mechanical safety testing, RoHS compliance | The entry pass for the European market; electrical equipment must meet LVD (Low Voltage Directive) and EMC Directive requirements, and sometimes RoHS compliance. | Applicable for all electrical equipment entering the European market. |

| LVD Directive (2014/35/EU) | Low Voltage Electrical Equipment (50-1000V AC / 75-1500V DC) | Insulation testing, withstand voltage testing, leakage current testing, continuity testing | Requires safety assurance within specified voltage ranges, with full compliance declarations. Must meet IEC and EN standards. | Key component of CE certification for the European market. |

6. Ensuring Testing Efficiency and Accuracy

6.1 Automation and Data Systems

The integration of Automated Test Equipment (ATE) and Data Acquisition Systems (DAS) has revolutionized power testing, addressing the demand for precision and scalability in complex testing environments:

- Automated Test Equipment (ATE):

- Facilitates high-speed, repeatable testing, minimizing human error.

- Supports complex scenarios such as dynamic load changes and multi-channel measurements.

- Advanced ATE systems feature AI-driven algorithms to optimize test parameters in real-time.

- Data Acquisition Systems (DAS):

- Provide continuous, high-resolution monitoring of critical parameters like voltage, current, and temperature.

- Enable integration with cloud-based platforms for remote analysis and predictive maintenance.

- Modern DAS systems include robust data visualization tools, enhancing decision-making through actionable insights.

6.2 Process Design

Effective test process design is pivotal for maximizing efficiency and ensuring consistency:

- Clear Test Steps and Standards:

- Establish precise protocols aligned with international standards such as IEC, UL, and IEEE.

- Incorporate validation checkpoints to ensure compliance and traceability.

- Workflow Optimization:

- Implement parallel testing techniques to reduce overall testing time.

- Leverage modular test setups to accommodate diverse product lines with minimal reconfiguration.

- Use automated test scheduling systems to streamline resource allocation and avoid bottlenecks.

6.3 Results Analysis

Advanced analytics transforms raw test data into actionable intelligence, uncovering trends and anomalies:

- Statistical Analysis:

- Apply regression models and machine learning algorithms to identify correlations between test parameters and performance outcomes.

- Utilize real-time anomaly detection to flag potential issues during testing.

- Continuous Improvement:

- Implement a feedback loop where test results inform product design and manufacturing processes.

- Leverage historical data to predict and mitigate future issues, reducing costs and downtime.

7. Future Trends in Power Testing

7.1 Smart Grids and Intelligent Equipment

The shift toward smart grids necessitates power testing solutions capable of:

- Adaptive Testing:

- Dynamically adjust test parameters based on grid conditions and load profiles.

- Enable real-time monitoring and optimization for distributed energy resources.

- Fault Prediction:

- Employ AI to forecast potential failures, reducing downtime and maintenance costs.

7.2 Regenerative Power Supply Technology

- Energy Recycling:

- Recover and reintegrate excess energy generated during testing into the grid, promoting sustainability.

- Supports high-efficiency applications in EV charging and renewable energy systems.

- Enhanced Simulation Capabilities:

- Simulate complex grid conditions, such as harmonic distortions and transient events, to ensure equipment resilience.

7.3 IoT Integration

- Remote Monitoring:

- Utilize IoT-enabled devices to monitor testing processes across multiple locations.

- Enable engineers to perform diagnostics and software updates remotely, saving time and resources.

- Data-Driven Insights:

- Aggregate and analyze data from IoT-connected testing equipment to optimize performance and predict future testing needs.

Why Choose Professional Power Testing Solutions?

Professional power testing ensures the safety, reliability, and compliance of products, crucial for accessing global markets and building brand trust.

Advantages of Infinipower Solutions:

- Cutting-Edge Technology: Harnesses the latest advancements in testing equipment and methodologies.

- Comprehensive Solutions: Tailored to meet diverse application needs, from industrial machinery to renewable energy systems.

- Global Support Network: Ensures timely technical assistance and localized expertise to address customer needs worldwide.

About Infinipower: Infinipower is a leader in delivering innovative, high-efficiency power solutions tailored for industrial, automotive, and renewable energy applications. Our expertise in power management drives sustainable energy goals and empowers customers to navigate the challenges of modern energy demands with confidence.