As the global electric vehicle (EV) market expands, onboard electronic systems, charging equipment, and vehicle control units inevitably face various electromagnetic interference (EMI) challenges. To ensure that electronic devices operate reliably in complex electromagnetic environments and comply with international regulatory standards, the IEC 61000 series has become a crucial technical benchmark for EV testing and certification. This article offers an in-depth look at the basic concepts and components of the IEC 61000 series, its application in EV testing, and a comparison with other international standards. We also examine case studies from the Taiwan market and provide a practical guide—from design through testing—to achieving full EMC compliance.

1. Introduction and Background

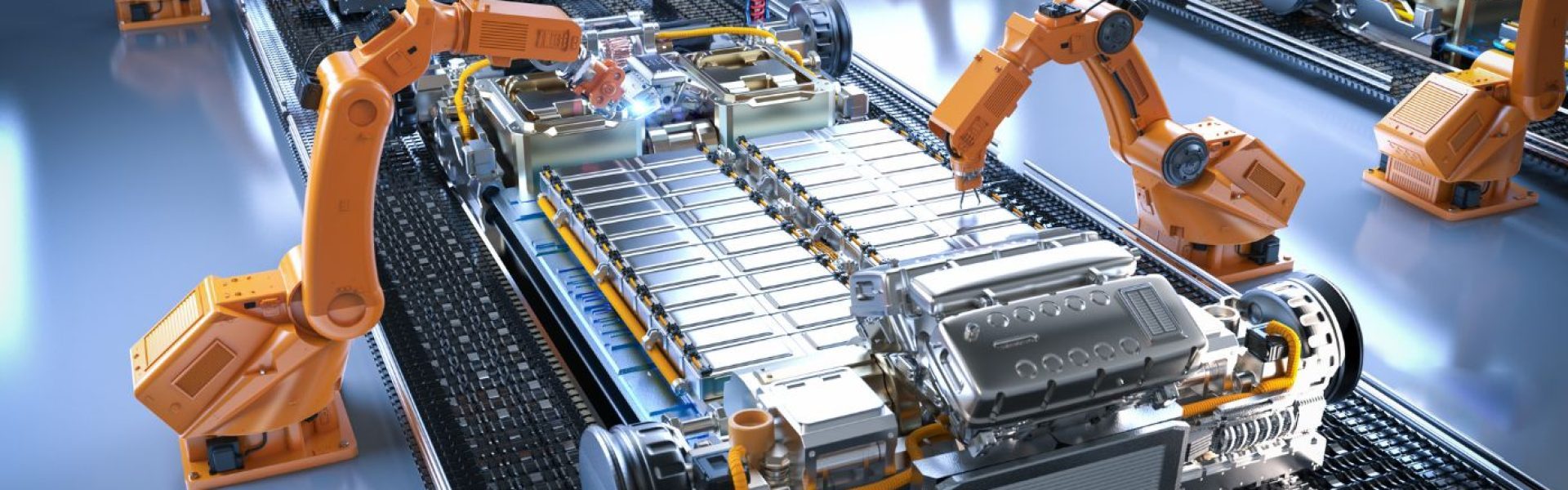

1.1 The Growth of the Electric Vehicle Industry and the Importance of EMC Testing

With increasing environmental awareness and demands for energy conservation and emissions reduction, electric vehicles have emerged as a key component of future smart mobility. EVs incorporate high-voltage batteries, inverters, charging systems, onboard electronics, and communication devices. Each of these components can generate significant electromagnetic interference (EMI) during operation. EMI can not only disrupt vehicle systems such as navigation, communication, and safety controls but also adversely affect other electronic devices. Therefore, comprehensive electromagnetic compatibility (EMC) testing—from the early design phase to full-vehicle testing—is essential for ensuring vehicle safety, operational stability, and international regulatory compliance.

1.2 Taiwan’s Market and Government Initiatives

Taiwan is one of the major hubs for the global EV industry. Both government agencies and industry stakeholders are actively promoting EMC testing and certification. Organizations such as the Automotive Research & Testing Center (ARTC) and the Bureau of Standards, Metrology and Inspection (BSMI) are working to establish EV EMC testing platforms that integrate international standards with local requirements. This comprehensive approach helps manufacturers achieve full-process testing from individual components to complete vehicles, thereby enhancing product quality and market competitiveness. These initiatives not only meet international standards but also create more opportunities for companies in the global marketplace.

2. Overview of the IEC 61000 Series Standards

The IEC 61000 series, developed by the International Electrotechnical Commission (IEC), provides a framework for electromagnetic compatibility (EMC) by regulating emissions and immunity requirements for electronic equipment. It includes detailed test methods and technical requirements designed to ensure that devices operate reliably in various electromagnetic environments.

2.1 Main Components of the IEC 61000 Series

The following table outlines the main parts of the IEC 61000 series along with their descriptions and primary applications:

| Standard Number | Description | Main Application |

|---|---|---|

| IEC 61000-1 | General Definitions and Terminology | Provides the foundational terminology and framework for EMC testing across other standards. |

| IEC 61000-2 | Environment Standards | Describes electromagnetic environment parameters, interference sources, and background noise levels. |

| IEC 61000-3 | Standards for Harmonics and Voltage Fluctuations in Power Systems | Controls harmonics and voltage fluctuations in power systems to protect stability. |

| IEC 61000-4 | Testing and Measurement Techniques | Provides test methods for immunity to ESD, fast transient, surge, conducted interference, etc. |

| IEC 61000-5 | Installation and Mitigation Guidelines | Offers guidance on reducing EMI impacts through design, cabling, grounding, and shielding measures. |

2.2 Basic Concepts of EMC

Before diving into the specifics of the IEC 61000 series, it is important to understand two core concepts:

- Electromagnetic Interference (EMI): The unwanted electromagnetic energy generated by a device during operation that may disturb the functioning of other electronic devices.

- Electromagnetic Susceptibility (EMS): The ability of a device to continue functioning normally when exposed to external electromagnetic disturbances.

Together, these concepts form the basis of electromagnetic compatibility (EMC). The IEC 61000 series standards are built upon these principles, providing detailed test parameters and methods for various environmental conditions and application scenarios.

3. Application of IEC 61000 in EV EMC Testing

Electric vehicles contain multiple electronic components and high-voltage systems that generate strong electromagnetic fields. To ensure the stability and safety of vehicle systems, comprehensive testing in accordance with the IEC 61000 standards is essential.

3.1 Challenges for Onboard Electronic Devices

Electric vehicles typically feature a variety of electronic devices, including infotainment systems, navigation modules, onboard communications, and sensors. These devices not only may act as sources of EMI but can also be affected by interference from high-power components such as batteries and inverters. Common challenges include:

- Signal Interference and Data Loss: When multiple electronic systems operate in the same electromagnetic environment, interference among signals can result in communication failures or data corruption.

- System Malfunction: Even minor interference in critical safety systems (e.g., advanced driver-assistance systems) may lead to system failures, posing safety risks.

- Regulatory Non-compliance: Failure to pass international certification (such as CE, FCC, or SAE standards) can prevent market entry.

3.2 EMC Challenges for High-Voltage Components

High-voltage batteries, inverters, and charging devices in EVs generate strong electromagnetic fields during charge/discharge and inverter operations. These high-frequency disturbances can interfere with the normal operation of lower-voltage onboard electronics. Thus:

- EMI Noise Control: Effective shielding, filtering, and proper grounding must be implemented to minimize EMI from high-voltage components.

- Simulation of Testing Environments: The IEC 61000 series provides various test methods (e.g., ESD, fast transient, surge, and conducted immunity tests) to simulate real-world electromagnetic environments and validate the immunity of the product.

3.3 Typical Testing Scenarios and Corresponding Standards

The table below summarizes common EMC testing scenarios in electric vehicles along with the corresponding IEC 61000 standards:

| Test Type | Relevant Standard | Application Scenario |

|---|---|---|

| Electrostatic Discharge (ESD) Test | IEC 61000-4-2 | Simulates electrostatic discharge when a person or object contacts the device; evaluates immunity. |

| Fast Transient (Burst) Test | IEC 61000-4-4 | Simulates short-duration voltage pulses due to switching or relay operations; checks control unit stability. |

| Surge Test | IEC 61000-4-5 | Assesses device endurance against high-voltage surges from lightning or power fluctuations. |

| Radiated Immunity Test | IEC 61000-4-3 | Verifies the performance of onboard communication, navigation, and infotainment systems under strong electromagnetic fields. |

| Conducted Immunity Test | IEC 61000-4-6 | Evaluates the immunity of devices to radio frequency interference conducted via power or signal cables. |

These tests help engineers predict and resolve potential EMC issues before mass production, ensuring vehicle systems remain robust in real-world operating conditions.

4. Detailed Test Methods of the IEC 61000-4 Series

The IEC 61000-4 series specifies detailed technical procedures for various immunity tests. Below, we highlight several commonly used test methods.

4.1 Electrostatic Discharge (ESD) Test — IEC 61000-4-2

Objective:

Simulate the electrostatic discharges generated when a person or object contacts the device, verifying that the equipment continues to operate normally without data loss or malfunction.

Test Procedure:

- An ESD generator is used to simulate both contact discharges and air discharges.

- Test points typically include exposed metal parts, buttons, and interfaces.

Test Parameters:

| Test Type | Voltage Range | Discharge Interval | Number of Tests |

|---|---|---|---|

| Contact Discharge | ±2 kV to ±8 kV | 1 s to 5 s | At least 10 tests per point |

| Air Discharge | ±2 kV to ±15 kV | 1 s to 5 s | At least 10 tests per point |

4.2 Fast Transient (Burst) Test — IEC 61000-4-4

Objective:

Simulate fast transient pulses induced on power or signal lines by switching operations or relay actions, evaluating the device’s ability to withstand short-duration high-voltage pulses.

Test Procedure:

- A burst pulse generator is used to simulate fast transient disturbances.

- The test device is connected to both the power and signal lines while interference signals are applied.

Test Parameters:

| Parameter | Test Value |

|---|---|

| Pulse Amplitude | ±0.5 kV to ±4 kV |

| Pulse Repetition Rate | 5 kHz or 100 kHz |

| Test Duration | 1 minute per phase |

4.3 Surge Test — IEC 61000-4-5

Objective:

Assess the device’s endurance when subjected to high-voltage surges caused by lightning or power grid disturbances, ensuring stable operation under sudden voltage spikes.

Test Procedure:

- A surge generator injects high-voltage surge signals into the device’s power input.

- Testing is conducted while the device is operating normally to simulate real-world conditions.

Test Parameters:

| Parameter | Test Value |

|---|---|

| Surge Voltage | ±0.5 kV to ±6 kV |

| Surge Waveform | 1.2/50 µs |

| Polarity | Both positive and negative polarity must be tested |

4.4 Conducted Immunity Test — IEC 61000-4-6

Objective:

Simulate the interference conducted via power or signal cables from radio frequency sources, evaluating the device’s immunity to such interference.

Test Procedure:

- A Coupling/Decoupling Network (CDN) is used to inject RF interference signals into the device’s cables.

- The frequency range for testing typically spans from 150 kHz to 80 MHz.

Test Parameters:

| Parameter | Test Value |

|---|---|

| Interference Signal Level | 3V to 10V |

| Frequency Range | 150 kHz to 80 MHz |

| Modulation Method | Sine wave AM modulation |

By employing these detailed test methods, engineers can thoroughly verify the immunity of vehicle systems against various electromagnetic disturbances, thereby reducing the risk of failures during mass production.

5. Comparison of IEC 61000 with Other International Standards

In the global EV market, different regions use varying standards for EMC testing. Below is a comparison of the IEC 61000 series with SAE, ISO, and GB standards to help manufacturers select the most appropriate guidelines for international certification.

5.1 Advantages of IEC 61000

- Global Applicability:

Developed by the International Electrotechnical Commission, the IEC 61000 series enjoys worldwide recognition and is applicable across diverse industries. - Detailed Technical Specifications:

The standard provides comprehensive parameters—from definitions and test methods to installation guidelines—ensuring consistent and repeatable test results. - Full-Process Coverage:

It covers emissions, immunity, installation, and mitigation, addressing all critical aspects of EMC compliance.

5.2 Differences Between IEC 61000 and SAE, ISO, GB Standards

| Standard | Application Field | Test Coverage | Key Features |

|---|---|---|---|

| IEC 61000 | Cross-industry (Global) | Comprehensive EMI emissions and immunity coverage | Detailed specifications; comprehensive and internationally recognized |

| SAE Standards | Automotive (primarily for North America) | Focuses on onboard electronics and complete vehicle systems | Tailored for automotive applications; certain test methods are simplified |

| ISO Standards | Multiple industries including automotive and industrial sectors | Primarily addresses transient voltages and some EMI emissions | Narrower test range; emphasizes transient voltage issues |

| GB Standards | Domestic products in China | Partially aligned with IEC 61000 series | Gradually converging with international standards, but with some technical differences |

As shown in the table, the IEC 61000 series is favored for its comprehensive scope and detailed technical guidelines, making it the primary reference for EMC testing in electric vehicles. Manufacturers should base their design and certification processes on IEC 61000 while incorporating additional tests as required by target markets.

6. Case Studies and Latest Trends in the Taiwan Market

6.1 Government Policies and Initiatives in Taiwan

Taiwan’s government has been proactive in enhancing product quality and international competitiveness in the EV sector. The Ministry of Economic Affairs and the Bureau of Standards, Metrology and Inspection (BSMI) have spearheaded the establishment of complete vehicle EMC testing platforms. These initiatives offer comprehensive testing services—from components to whole vehicles—helping manufacturers rapidly achieve international certification while meeting domestic safety and environmental requirements.

6.2 Industry Innovations and Application Examples

Many Taiwanese manufacturers are leveraging advanced test equipment and in-house R&D to overcome challenges in EV EMC testing. For example:

- Charging Equipment Testing:

To address the EMC challenges posed by high-frequency switching and surge conditions in charging devices, companies are employing a combination of IEC 61000-4-5 surge tests and IEC 61000-4-2 ESD tests to ensure stable electromagnetic performance during charging. - Onboard Communication Module Testing:

For wireless communication systems within vehicles, manufacturers use IEC 61000-4-3 radiated immunity tests along with IEC 61000-4-6 conducted immunity tests to validate stable performance under strong electromagnetic fields. - Complete Vehicle Integration Testing:

Through collaboration with platforms such as the ARTC in Taiwan, companies integrate EMC simulation tools in the early design phase to optimize cabling and shielding designs, thereby reducing certification lead times.

6.3 Future Trends and Challenges

With the rapid development of wireless charging, 5G communication, and smart connected vehicles, EV EMC testing faces both challenges and opportunities:

- Challenges:

- High-frequency electromagnetic fields generated by high-voltage charging/discharging and wireless charging systems require more refined testing and control methods.

- Variations in international standards mean that manufacturers need to design multi-level testing schemes tailored to different regional requirements.

- Opportunities:

- Emerging technologies drive the adoption of automated and smart testing equipment, significantly enhancing test efficiency and accuracy.

- International cooperation and standard harmonization may reduce duplicate certification efforts, expanding market access globally.

7. A Full-Process Strategy for Achieving Complete EMC Compliance

7.1 EMC Prevention in the Design Phase

Incorporating EMC control early in product development is crucial:

- PCB Layout:

A well-designed printed circuit board with proper routing, grounding, and shielding minimizes EMI generation. - Simulation Tools:

Using EMC simulation software to predict potential interference issues allows designers to optimize the design in advance. - Component Selection:

Choosing components and filters that comply with IEC 61000 standards helps control EMI at the source.

7.2 Optimizing the Testing and Verification Process

A comprehensive verification process—from pre-testing and prototype testing to final certification—requires full-process control:

- Automated Testing Equipment:

Employing high-precision automated testing systems that support data analysis based on IEC 61000 series can dramatically reduce test durations and human errors. - Data Collection and Analysis:

Detailed statistical analysis of test data enables timely design adjustments, reducing rework risks. - Cross-Department Collaboration:

Close coordination among R&D, testing, and quality management teams ensures that the entire vehicle system complies with EMC requirements throughout design and production.

7.3 The Importance of Partnering with Professional Service Providers

Collaborating with experienced third-party testing laboratories and technical service providers can shorten the time-to-market and improve certification success rates. In Taiwan, INFINIPOWER is a trusted partner renowned for its advanced automated test equipment and comprehensive technical support in the EV EMC testing domain.

8. Conclusion and Future Outlook

The IEC 61000 series standards serve as the authoritative benchmark for electromagnetic compatibility testing. They provide a complete suite of test methods—from ESD to surge, fast transient, and conducted immunity tests—and are essential for ensuring that EV systems operate safely and reliably. As the global EV market becomes increasingly competitive, a full-process approach—from design to certification—will remain a key driver for improving product quality and market competitiveness.

Looking ahead, rapid technological advances such as wireless charging, 5G communications, and smart connected vehicles will prompt continual updates to the IEC 61000 standards. Manufacturers should stay abreast of these international developments and adopt automated, smart testing equipment to expedite certification processes and secure a competitive edge globally.

9. Infinipower’s Professional Testing Solutions

To help companies quickly meet the requirements of IEC 61000 standards in EV EMC testing, Infinipower Power Supply Co., Ltd. offers a comprehensive range of advanced testing equipment and solutions:

- Advanced Test Equipment:

Featuring programmable AC/DC power supplies, surge generators, fast transient test systems, ESD generators, and Coupling/Decoupling Networks (CDNs) that fully cover the IEC 61000 series test requirements. - Automated Test Systems:

High-efficiency, high-precision automated testing software that significantly shortens test cycles, minimizes manual errors, and generates detailed test reports. - Expert Technical Support:

Our professional team provides full-cycle technical assistance—from the initial design phase through final certification—ensuring your product enters the market swiftly and successfully.

Contact Infinipower today to learn more about our complete EMC testing solutions for electric vehicles and gain the competitive advantage needed to lead in the global market!

References (APA Format)

International Electrotechnical Commission. (n.d.). IEC 61000-4-3: Electromagnetic compatibility (EMC) – Part 4-3: Testing and measurement techniques – Radiated, radio-frequency, electromagnetic field immunity test. Retrieved from https://webstore.iec.ch/en/publication/70473

BSMI. (n.d.). Electromagnetic Compatibility Testing. Retrieved from https://www.bsmi.gov.tw

MOEA. (n.d.). Electric Vehicle Charging Equipment Product Safety Certification. Retrieved from https://www.moea.gov.tw

ARTC. (n.d.). Complete Vehicle Electromagnetic Compatibility Testing Platform. Retrieved from https://www.artc.org.tw

SAE International. (n.d.). Automotive EMC Standards. Retrieved from https://www.sae.org

ISO. (n.d.). ISO 7637 – Road vehicles – Electrical disturbances from conduction and coupling. Retrieved from https://www.iso.org

By reading this article, you now have a thorough understanding of the application of the IEC 61000 series in electric vehicle testing, the various test methods involved, and how they compare to other international standards. Whether it is optimizing design, streamlining the testing process, or achieving international certification, IEC 61000 provides the technical support you need.

Contact Infinipower today to harness our advanced EMC testing solutions and empower your products to excel in the global electric vehicle market!