The Importance of Automotive Ethernet in Electric Vehicles

As the automotive industry rapidly moves toward electrification and smart systems, the in-vehicle communication networks in electric vehicles (EVs) face increasingly complex demands. Traditional bus systems like CAN and LIN, once sufficient, now struggle with the massive data needs brought by advanced driver assistance systems (ADAS), infotainment systems (IVI), and battery management systems (BMS). These older systems can’t provide the high bandwidth, low delay, and scalability modern EVs require. As a result, Automotive Ethernet—which offers high-speed data transfer, low latency, and flexible expansion—has emerged as a core technology for future EV communication networks.

1. The Evolution of EV Architectures

Classic in-vehicle communication often relied on CAN or LIN buses. While these were fine for older cars, they are limited in bandwidth and cannot meet the rising demands of advanced EV functions. Their main issues include:

- Limited bandwidth: CAN’s maximum of about 1 Mbps and LIN’s 20 kbps can’t handle today’s large, continuous data streams from numerous sensors and modules.

- Increasing delays: Adding more ECUs (electronic control units) leads to unpredictable response times, problematic for real-time ADAS functions.

- Poor scalability: Traditional architectures are hard to rewire or upgrade when adding new features or modules.

Automotive Ethernet solves these problems by offering much higher data rates (ranging from 100 Mbps to 10 Gbps), more flexible network structures, and better support for future upgrades. Initially used for infotainment and camera systems, Automotive Ethernet now supports BMS, ADAS, and even drive systems, becoming the backbone of next-generation EV communications.

Advantages of Ethernet for EVs

- Higher Bandwidth & Efficiency:

Ethernet easily handles the large and continuous data streams from multiple sensors and cameras. Its high-speed links ensure low latency and reliable data flow, critical for real-time decisions in ADAS and energy management. - Greater Scalability:

Ethernet’s modular, hierarchical design makes it simpler to integrate new ECUs and sensors into the same network. Future upgrades or feature enhancements can be done with minimal rewiring, reducing development and production costs. - Weight and Cost Reduction:

Using Ethernet (including single-pair Ethernet) can lower the amount of cabling needed. This reduces both complexity and vehicle weight, which in turn lowers costs and improves overall vehicle efficiency.

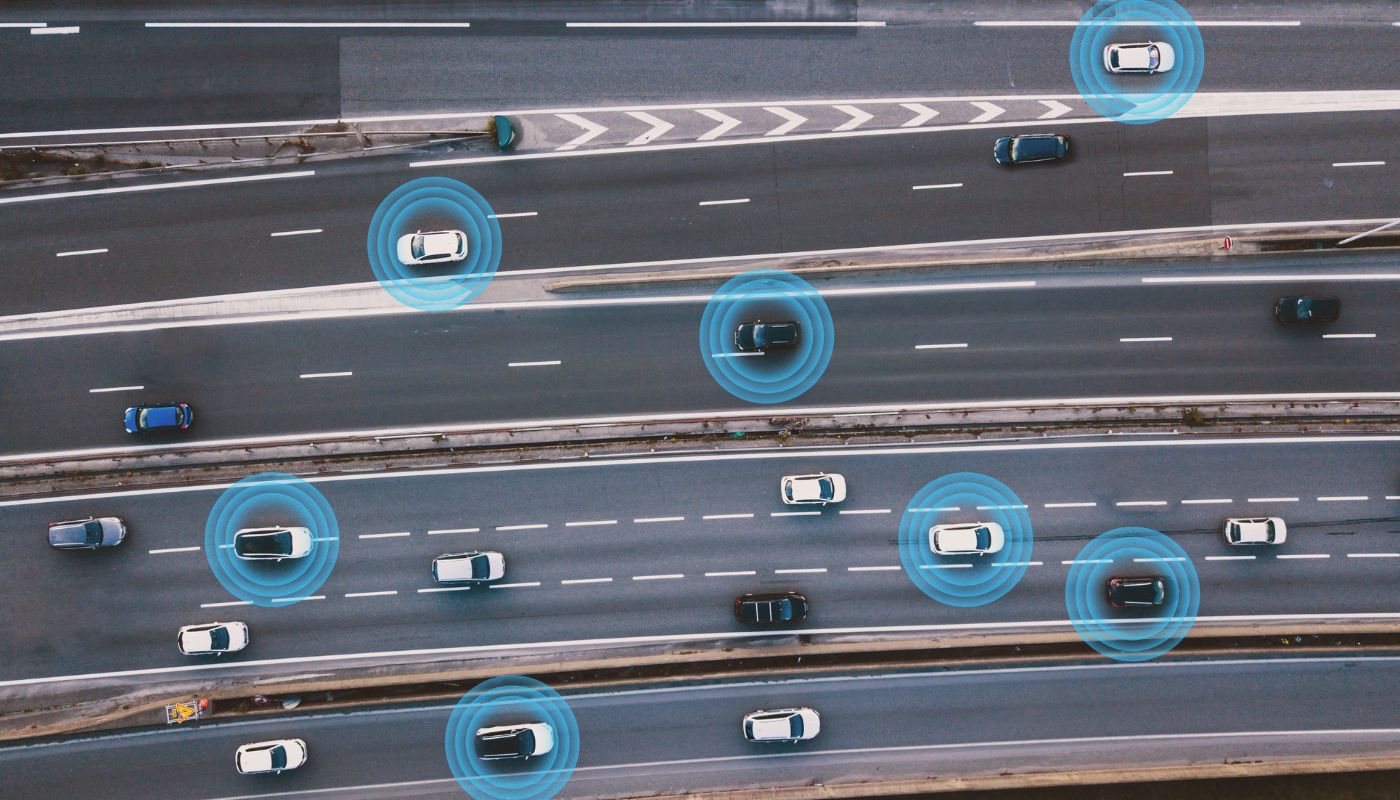

Automotive Ethernet and Vehicle-to-Everything (V2X)

As cars evolve into connected devices within the broader smart transportation system, Automotive Ethernet provides the speed and reliability needed for V2X communications—connecting the car to other vehicles, infrastructure, and pedestrians. This robust communication network is essential for higher levels of automation, safe autonomous driving, and intelligent traffic systems.

- Supporting V2X: High-speed Ethernet ensures the car can quickly exchange real-time data with traffic lights, road signs, and other vehicles.

- Enabling Higher-Level Autonomy: Ethernet’s reliable, high-bandwidth communication helps power advanced autonomous driving features that rely on instantaneous data exchange.

- Core to Future Smart Mobility: In the future, the car will be a node in a larger mobility network. Automotive Ethernet will form the communication backbone, connecting the vehicle with cloud services and smart city infrastructure.

In short, Automotive Ethernet solves the limitations of old bus systems while laying a solid foundation for connected, intelligent EVs.

2. Practical Applications of Automotive Ethernet in EVs

As EVs gain more functionality, their internal communication grows more complex. Automotive Ethernet steps in to handle these demands efficiently. Let’s look at some key applications:

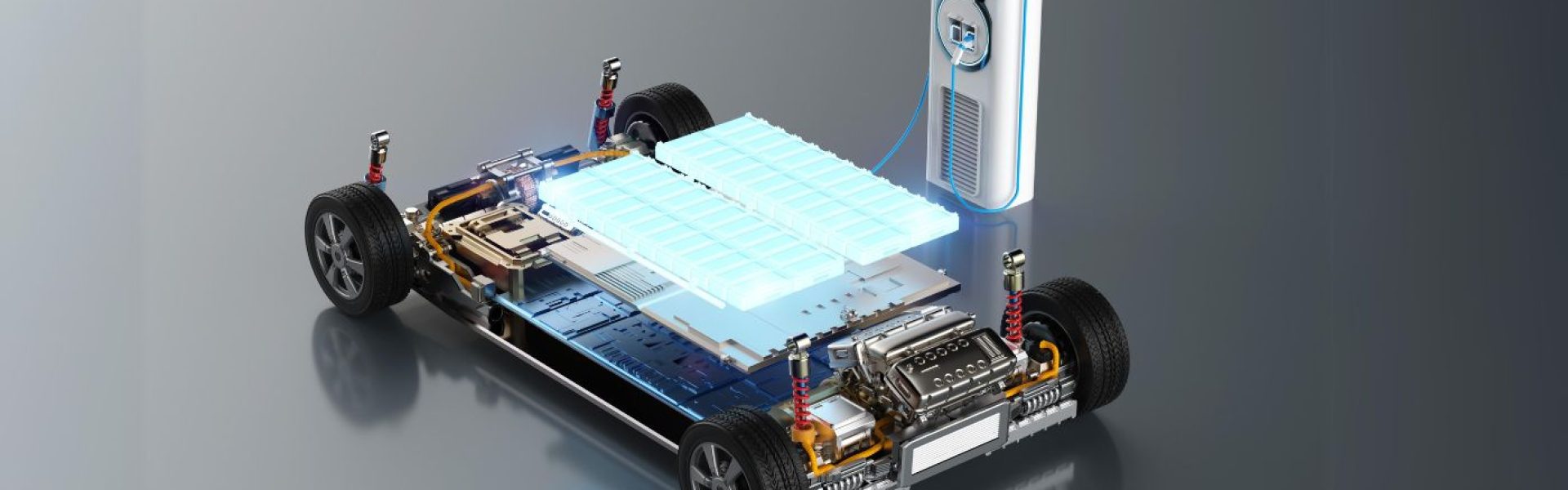

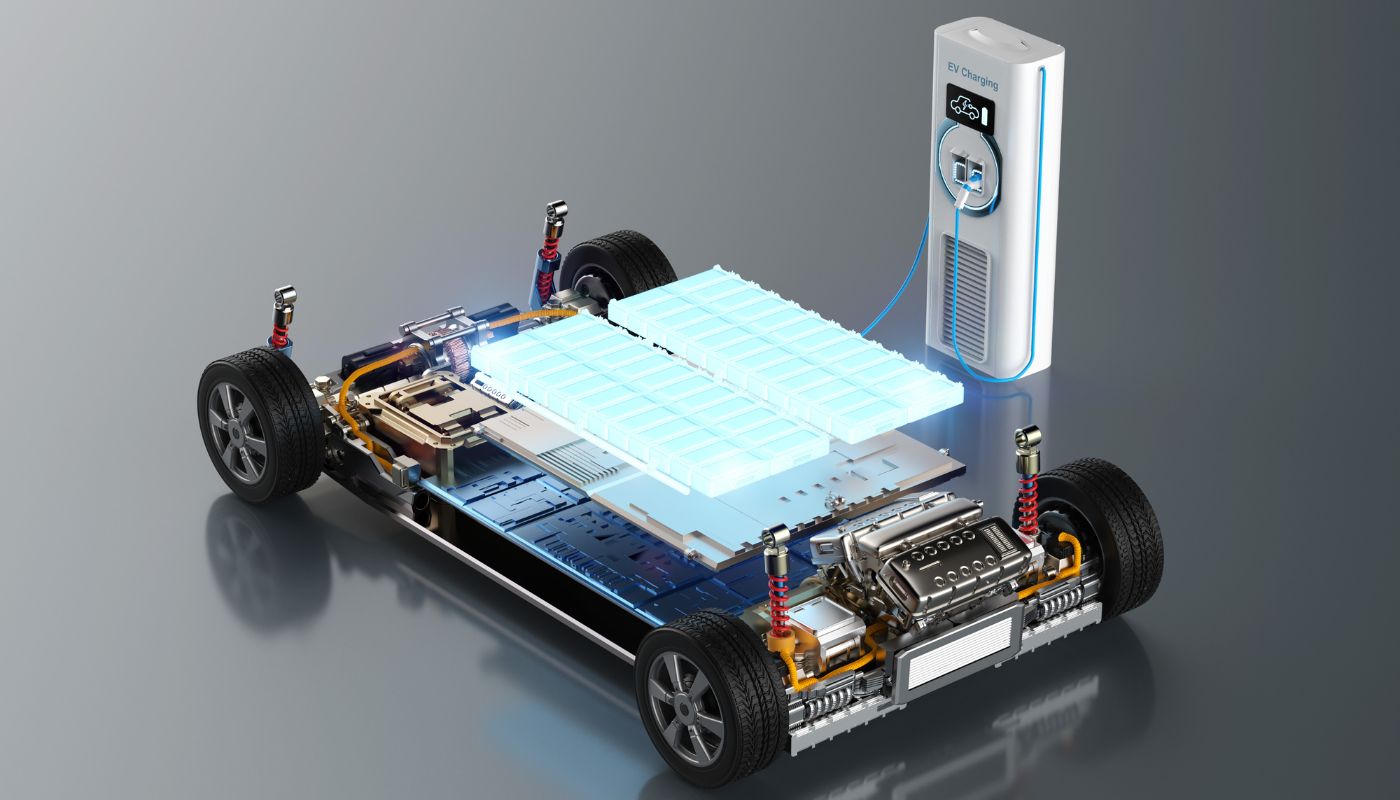

Battery Management Systems (BMS) and Power Modules

The BMS monitors battery health, controls charging, and ensures optimal battery performance. As EVs use bigger battery packs and more complex modules, the old CAN bus struggles to handle the increased data load. Ethernet’s high bandwidth lets all battery modules share voltage, temperature, and current data quickly and precisely. This fast data exchange helps prevent delays that could cause safety issues and improves overall battery system performance—especially during energy recovery or fast charging.

ADAS and Sensor Fusion

ADAS relies on data from cameras, radar, LiDAR, and other sensors. These sensors generate huge amounts of data that must reach a central controller in real-time. CAN and LIN can’t keep up. Ethernet, with its Time-Sensitive Networking (TSN), ensures all sensor data arrives synchronized and on time. This leads to accurate environment perception and safer, more reliable semi- or fully autonomous driving. As ADAS sensors and complexity grow, Ethernet will remain critical for handling data-intensive applications.

In-Vehicle Infotainment (IVI) and Connectivity

Consumers expect rich in-car entertainment: multiple high-resolution screens, streaming content, Wi-Fi hotspots, and mobile device integration. Older networks can’t support these high-quality video and audio streams simultaneously. Ethernet easily carries HD video and other data feeds at once, allowing passengers to enjoy seamless content. It also supports faster communication with external devices, enabling new features like integrated smartphones, remote vehicle monitoring, and data sharing. Ethernet’s high bandwidth and low latency greatly enhance the in-car digital experience.

In all these examples—BMS, ADAS, and IVI—Automotive Ethernet excels in providing efficient, reliable, and scalable communication.

3. Challenges in Testing Automotive Ethernet for EVs

While Ethernet brings many benefits, ensuring it runs reliably in the tough automotive environment is a challenge. EVs face extreme temperatures, vibrations, and electromagnetic interference (EMI). With more ECUs and sensors than ever, achieving perfect synchronization and security is critical. Three key testing challenges are:

- High-Frequency Data Reliability:

High data rates mean signal integrity and EMI issues. Vibration, wiring quality, and noise from electric motors can distort signals and cause data loss. Testing involves using oscilloscopes and analyzers to ensure stable, noise-resistant transmissions. - Network Synchronization and Low Latency:

Time-sensitive tasks (like sensor fusion) demand perfectly synchronized data. TSN protocols require precise timing tests to ensure data arrives exactly when needed. Specialized TSN test tools measure latency and verify time alignment across all ECUs. - Security in Cross-Module Communication:

Ethernet’s openness means potential hacking risks. Attackers could target infotainment systems or V2X units as a backdoor into the vehicle’s core functions. Security testing involves simulating cyber-attacks, checking encryption methods, and verifying identity/authentication protocols to ensure data integrity and safe operation.

4. Technical Approaches to Automotive Ethernet Testing

To ensure robust and secure Automotive Ethernet in EVs, manufacturers use a range of test tools and methods:

- Physical Layer Testers (PHY):

Check signal integrity, timing, and noise levels at high data rates. Essential for spotting weak spots in wiring or connectors. - Packet Analyzers:

Capture and inspect data packets, detect lost or duplicated packets, and verify protocol correctness. - TSN Testing Tools:

Validate real-time data delivery, time synchronization, and prioritization under various load conditions. - Security Testing Tools:

Simulate attacks, test encryption and authentication, and ensure the network can handle potential hacks, keeping data safe.

Manufacturers often combine multiple test solutions (hardware and software) to cover physical, data link, transport, and application layers thoroughly.

5. Real-World Challenges for EV Manufacturers Like BYD

Leading EV makers, such as BYD, are already integrating Ethernet in their cars. As they add more ECUs and increase complexity, they need even higher bandwidth and more extensive testing:

- Scalability:

Future EVs may need 2.5Gbps, 5Gbps, or even 10Gbps Ethernet links. BYD and others must ensure these higher-speed links remain stable in all conditions. - Strict Standards Compliance:

As Ethernet spreads, stricter test standards emerge, including TSN consistency tests and cross-system security checks. Meeting these standards ensures higher network stability and safety.

6. Building an Efficient Automotive Ethernet Test Process

An effective test process includes:

- Comprehensive Test Planning:

Include static tests (vehicle parked, stable conditions), dynamic tests (vehicle in motion, rough roads), long-duration tests, and extreme environmental tests (very hot, cold, or humid). - Combining Simulation and On-Road Testing:

Start with simulations (lab conditions) to spot early issues, then verify solutions in real vehicles. This approach saves time and money, identifying and fixing problems earlier. - Automation:

As networks grow complex, automated test tools help run repeated test scenarios quickly, reduce manual labor, and improve reliability. Automated platforms can generate test cases, monitor results, and produce detailed reports.

7. Conclusion and Future Outlook

Automotive Ethernet has become a cornerstone for EV communications. As autonomous driving, V2X, and smart mobility advance, Ethernet will evolve with higher speeds and even more robust features. It will enable cars to seamlessly connect to the outside world, support complex onboard functions, and help create smarter transportation systems.

Car manufacturers and suppliers must continue refining their test processes and tools to manage the increasing complexity and ensure stability, safety, and security.

Choose Infinipower’s Test Power Solutions

Infinipower’s expertise in high-power regenerative AC sources, battery test systems, and high-power-density bidirectional power units helps you achieve top-notch reliability and performance in EV and new energy equipment testing.

- Advanced R&D and Leadership: Over 15 years of experience integrating technical features, regulatory requirements, and innovative functions.

- Confidence in Performance and Compliance: Our stable, accurate test power sources let you focus on innovation and safety.

- Quality, Stability, and Reliability: Validated by top global manufacturers, produced in world-class facilities.

Contact our technical team to learn how Infinipower’s test solutions can boost your product performance and competitiveness!