In today’s technology‐driven world, maintaining high-quality electrical power is crucial to the smooth operation of any modern facility. Harmonic testing plays a pivotal role in ensuring that power systems operate efficiently and reliably by detecting and analyzing unwanted distortions known as harmonics. These harmonics are generated by non-linear loads—such as computers, LED lighting, variable frequency drives, and other electronic devices—that draw current in ways that deviate from a purely sinusoidal waveform.

Harmonic testing is essential not only for compliance with industry standards but also for safeguarding critical equipment, reducing energy waste, and preventing unplanned downtime. This guide offers a comprehensive overview of harmonic testing, discussing its technical fundamentals, the importance of regular testing, and the various industries that can benefit from it. We also address long-tail keyword search queries and user intent to help you better understand why harmonic testing matters for your facility.

Background and Fundamentals of Harmonics

What Are Harmonics?

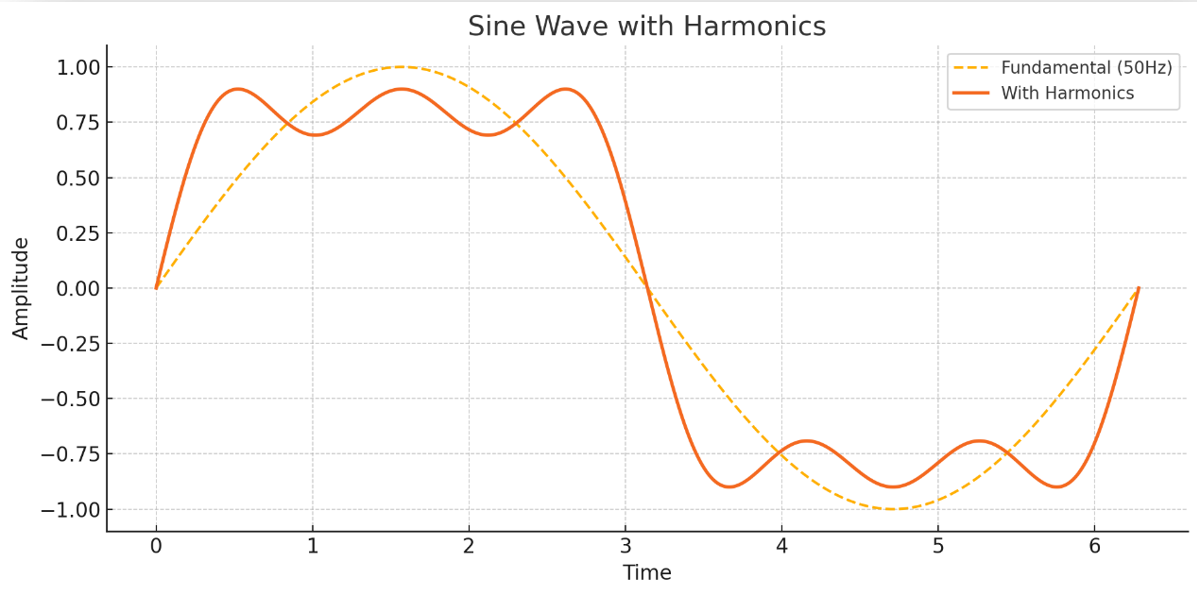

Harmonics refer to voltage or current components in an electrical system that operate at frequencies that are integer multiples of the fundamental frequency (typically 50 Hz or 60 Hz). For example, if the fundamental frequency is 60 Hz, the 3rd harmonic is 180 Hz, the 5th harmonic is 300 Hz, and so on. These additional frequencies can distort the normal sinusoidal waveform of the power supply.

There are several key aspects to consider:

- Types of Harmonics:

- Odd Harmonics: Generally the most common in power systems, these include the 3rd, 5th, 7th, etc. They tend to have a significant impact on the performance of electrical equipment.

- Even Harmonics: Although less common, these can be generated by specific types of equipment and may still contribute to overall distortion.

- Causes of Harmonics:

Non-linear loads are the primary culprits. Devices such as variable frequency drives, computers, printers, fluorescent lighting, and switching power supplies convert AC to DC (or vice versa) in a manner that creates these additional frequencies. - Effects of Harmonics:

The presence of harmonics in a power system can lead to several issues:- Increased Heating: Transformers, motors, and cables may overheat due to additional losses.

- Equipment Malfunction: Sensitive electronics and control systems can suffer from erratic behavior or premature failure.

- Reduced Efficiency: Harmonics result in wasted energy and increased operational costs.

- Interference: Communication lines and signal cables may experience interference, affecting overall system performance.

For a deeper look into the basic principles behind power testing, please explore our Basic Knowledge of Power Testing resource page.

The Science Behind Harmonic Distortion

The ideal electrical power waveform is a perfect sine wave. However, when non-linear loads draw current, the resulting waveform deviates from this ideal shape. Fourier analysis allows engineers to decompose these complex waveforms into their constituent sinusoidal components—the fundamental frequency plus its harmonics. Understanding this decomposition is crucial for diagnosing power quality issues and designing appropriate mitigation strategies.

Standards such as IEEE Standard 519 provide guidelines on acceptable levels of harmonic distortion. Compliance with these standards is essential for ensuring that power systems do not suffer from the detrimental effects of excessive harmonic levels.

Why Harmonic Testing Is Important

Harmonic testing is not merely a regulatory checkbox—it is a proactive measure that can save companies substantial costs over the lifetime of their equipment. Here are several reasons why harmonic testing is crucial:

1. Ensuring Consistent Power Quality

Quality power is the backbone of modern industrial and commercial operations. By conducting harmonic tests, engineers can ensure that the power delivered to sensitive equipment remains within acceptable limits. This not only preserves the functionality of the equipment but also protects the overall system from cascading failures. For facilities that rely on precision electronics or computerized controls, even minor deviations in power quality can lead to significant disruptions.

2. Preventing Equipment Damage and Unplanned Downtime

Excessive harmonics can cause overheating and vibration in electrical equipment. Over time, this can lead to premature degradation of components such as motors, transformers, and capacitors. Regular harmonic testing allows facility managers to identify problematic areas before they result in costly equipment failures. Early detection through harmonic analysis is a key element of a robust preventive maintenance program, ensuring that repairs or upgrades can be scheduled during planned maintenance windows.

3. Improving Energy Efficiency

Energy waste is one of the hidden costs of poor power quality. Harmonic distortion forces electrical systems to operate less efficiently, leading to higher energy consumption and increased operating costs. By identifying and mitigating harmonics, facilities can improve their overall energy efficiency. This not only reduces energy bills but also contributes to environmental sustainability—a goal that is increasingly important to both businesses and regulators.

4. Enhancing System Reliability and Safety

Reliability is paramount in critical industries such as healthcare, data centers, and manufacturing. Electrical system failures can lead to severe consequences, including production losses, safety hazards, and even jeopardizing lives in medical settings. Through comprehensive harmonic testing, companies can ensure that their power systems are robust and less likely to fail unexpectedly. Maintaining high power quality through routine harmonic testing is an investment in long-term operational stability and safety.

How Harmonic Testing Is Conducted

Harmonic testing involves a systematic process that includes measurement, analysis, and interpretation. Below, we outline the key stages in a typical harmonic testing procedure:

Measurement

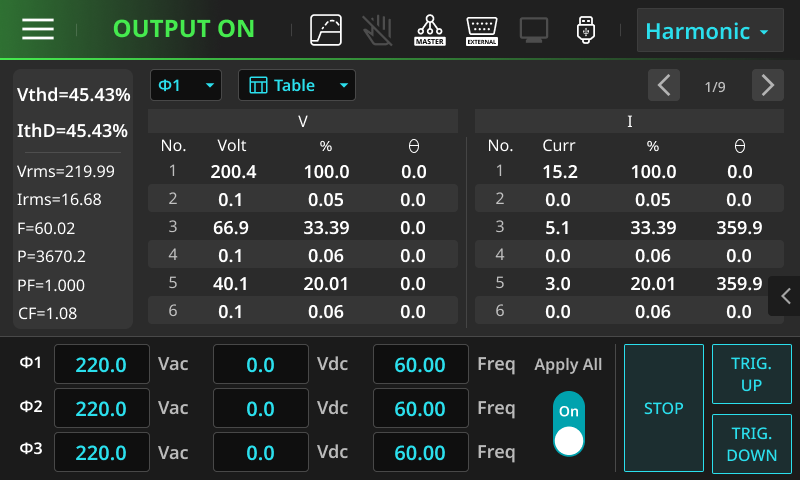

The first step in harmonic testing is to accurately capture the harmonic content of the electrical system. This is accomplished using specialized instruments such as power quality analyzers, spectrum analyzers, and oscilloscopes. These devices are designed to measure the voltage and current waveforms over a range of frequencies.

- Data Collection:

The instruments continuously record data over a predetermined period. This can include capturing transient events and steady-state conditions to ensure that the harmonic profile is fully characterized. - Signal Sampling:

High-speed sampling allows for detailed analysis of the waveform. Accurate sampling is essential to identify subtle harmonic components that might otherwise go unnoticed.

Analysis

Once data has been collected, it must be analyzed to determine the magnitude, frequency, and source of the harmonics. Fourier transform techniques, especially the Fast Fourier Transform (FFT), are commonly used for this purpose.

- Spectrum Analysis:

The FFT algorithm decomposes the complex waveform into its sinusoidal components, revealing the amplitude of each harmonic frequency. - Identification of Anomalies:

By comparing the measured harmonic levels against accepted standards (such as IEEE 519), engineers can identify potential issues. For example, unusually high levels of the 3rd or 5th harmonics might indicate a specific non-linear load that requires attention. - Data Visualization:

Graphical representations such as harmonic spectra, trend charts, and time-domain waveforms help in interpreting the results. Visual tools are crucial for communicating complex data to stakeholders who may not have a technical background.

Interpretation and Action

After analysis, the next step is to interpret the findings and decide on the necessary actions.

- Diagnosing Problems:

The data is used to pinpoint the sources of harmonic distortion. This might involve identifying a specific piece of equipment or a particular process that is contributing to the problem. - Developing Mitigation Strategies:

Once the source is identified, engineers can recommend corrective measures. These might include installing harmonic filters, upgrading equipment, or altering operating procedures to minimize non-linear loads. - Documentation:

Comprehensive reports are generated that detail the testing process, findings, and recommended actions. These reports serve as both a record of the current state of the power system and a roadmap for future improvements.

For more detailed technical insights, please refer to our Basic Knowledge of Power Testing page.

Industries That Benefit from Harmonic Testing

Harmonic testing is not a one-size-fits-all solution; its benefits are most pronounced in industries that rely heavily on stable and efficient electrical systems. Below are some key industries where harmonic testing is particularly critical:

1. Manufacturing

Modern manufacturing facilities are increasingly automated, relying on a myriad of electronic control systems and high-powered machinery. Variations in power quality can lead to inefficiencies, production halts, and even costly equipment failures. In such settings, harmonic testing is integral to:

- Ensuring Uninterrupted Production:

By maintaining high power quality, manufacturers can prevent unexpected downtime. - Protecting Expensive Machinery:

Regular harmonic testing helps identify issues before they lead to mechanical failures, thereby safeguarding costly assets. - Reducing Energy Costs:

Optimizing power quality directly contributes to energy savings—a critical factor in high-energy-consumption environments.

2. Data Centers

Data centers house thousands of servers and networking devices that require stable power for uninterrupted operation. Even minor disturbances can lead to data loss or system crashes. Harmonic testing in data centers:

- Prevents Critical Failures:

Detecting and mitigating harmonics ensures that power fluctuations do not compromise sensitive IT equipment. - Enhances Reliability:

Continuous monitoring of power quality helps maintain the high reliability standards that data centers must uphold. - Supports Scalability:

As data centers grow, maintaining optimal power quality through regular harmonic testing becomes essential for scalability and long-term performance.

3. Healthcare

Hospitals and medical facilities depend on a continuous, high-quality power supply for life-saving equipment such as ventilators, diagnostic machines, and imaging systems. In these environments, harmonic testing:

- Ensures Patient Safety:

Reliable power quality is critical to prevent malfunctions in medical equipment. - Reduces Maintenance Risks:

Early detection of power quality issues helps schedule preventive maintenance, minimizing the risk of equipment failure during critical operations. - Meets Regulatory Standards:

Healthcare facilities are often subject to stringent regulations, and regular harmonic testing helps ensure compliance with these standards.

4. Renewable Energy Installations

Renewable energy systems—such as solar farms and wind turbines—often use inverters to convert DC power into AC power. These inverters can introduce harmonics into the system. Harmonic testing in renewable energy installations:

- Optimizes Inverter Performance:

Identifying and mitigating harmonic distortion can improve the efficiency of the power conversion process. - Enhances System Integration:

As renewable energy sources are integrated into the grid, maintaining power quality is essential for overall system stability. - Supports Sustainability Goals:

By ensuring efficient operation, harmonic testing contributes to the sustainability and economic viability of renewable energy projects.

5. Commercial and Office Buildings

Modern office environments are equipped with a vast array of electronic devices—from computers and printers to HVAC systems and LED lighting. Harmonic testing in these settings:

- Controls Energy Consumption:

By minimizing distortions, facilities can reduce energy waste and lower operational costs. - Ensures Equipment Longevity:

Maintaining a clean power supply extends the lifespan of sensitive electronic equipment. - Improves Work Environment:

Reliable power quality contributes to a stable, comfortable environment for employees.

Incorporating Long-Tail Keywords and User Intent

A growing number of users are searching for specific, detailed information on harmonic testing. Long-tail keywords such as the following are frequently used:

- “Why is harmonic testing important for industrial power systems?”

- “How to measure harmonic distortion in commercial facilities”

- “Harmonic testing for energy efficiency improvement”

- “Preventing equipment damage with harmonic analysis”

These queries indicate that users are not just interested in the technical aspects but also in practical applications. They want to understand how harmonic testing can help reduce maintenance costs, improve energy efficiency, and extend equipment lifespan. By addressing these long-tail search terms and user intents within the article, we can provide comprehensive information that meets both technical and practical needs.

Future Trends and Innovations in Harmonic Testing

The field of power quality is continually evolving, and harmonic testing is no exception. Several trends are shaping the future of harmonic analysis:

Digitalization and IoT Integration

With the rise of the Internet of Things (IoT) and smart grid technologies, harmonic testing is becoming more automated and integrated into larger monitoring systems. Real-time data collection and analysis are enabling predictive maintenance approaches. Instead of simply reacting to problems, facilities can now anticipate potential issues before they become critical.

Advanced Data Analytics and Machine Learning

New analytical tools are being developed to better interpret the complex datasets generated by harmonic tests. Machine learning algorithms can detect patterns and predict future trends in power quality, allowing for more efficient scheduling of maintenance and system upgrades.

Improved Instrumentation

Technological advancements continue to improve the precision and usability of power quality analyzers. Modern instruments offer higher resolution, faster sampling rates, and enhanced connectivity, making it easier for engineers to perform comprehensive harmonic tests even in challenging environments.

Regulatory and Environmental Drivers

As energy regulations become stricter and companies aim for higher energy efficiency, harmonic testing will play an increasingly central role in compliance and sustainability initiatives. The adoption of international standards, such as IEEE 519, is expected to rise, ensuring that facilities worldwide maintain high power quality standards.

Case Studies and Real-World Applications

Consider a manufacturing facility that implemented regular harmonic testing as part of its preventive maintenance program. Prior to testing, the facility experienced frequent motor failures and unscheduled downtime. Through harmonic analysis, the facility identified a particular variable frequency drive that was producing excessive 3rd and 5th harmonics. After installing appropriate harmonic filters and adjusting the operating parameters, the facility saw a significant reduction in equipment failures, resulting in improved production efficiency and lower maintenance costs.

Another example is a data center that integrated continuous harmonic monitoring into its power management system. With hundreds of servers operating simultaneously, even minor power disturbances could lead to significant data loss. The facility used advanced spectrum analyzers to monitor harmonic levels in real time and quickly isolated a problematic UPS unit that was contributing to the overall distortion. Corrective measures not only stabilized the power supply but also improved overall system reliability, ensuring that critical IT services remained uninterrupted.

Conclusion

Harmonic testing is a vital process in modern power systems. By accurately measuring, analyzing, and mitigating harmonic distortion, facilities can ensure a stable and efficient power supply that protects equipment, reduces energy consumption, and minimizes downtime. Industries ranging from manufacturing and data centers to healthcare and renewable energy installations benefit from the insights provided by harmonic testing.

Regular harmonic testing is not just about meeting regulatory requirements—it is an investment in the long-term reliability and efficiency of your power system. As technology continues to advance, the integration of digital monitoring, advanced analytics, and predictive maintenance will further enhance the capabilities of harmonic testing.

For more detailed information and additional resources on power quality testing, please visit our About Us page and explore our Application Scenarios in Power Systems section. At InfiniPower, we are committed to providing innovative solutions that empower you to maintain optimal power quality in today’s demanding electrical environment.

References

- Arrillaga, J., Watson, N. R., & Chen, S. (2000). Power quality in electrical systems (2nd ed.). McGraw-Hill.

- Bollen, M. H. J. (2000). Understanding power quality problems: Voltage sags and interruptions. IEEE Press.

- IEEE. (2014). IEEE Standard 519-2014: Recommended practices and requirements for harmonic control in electrical power systems. IEEE.