To ensure that DC power supplies remain stable and reliable across various applications, engineers conduct several key tests. These tests focus on verifying voltage stability, dynamic response, ripple and noise levels, and overall reliability under extreme conditions. Each type of test checks how well a DC power supply can handle different loads and challenging situations. This article explains these critical testing methods and shows how they apply in real industrial scenarios.

Core DC Power Testing Techniques

1. Voltage and Current Stability Testing

What it checks:

This test measures how well the DC power supply holds its output voltage and current steady under different load conditions, from no load to full load.

Why it’s important:

A stable output ensures that the power supply can handle sudden load changes—such as going quickly from light load to heavy load—without large voltage or current fluctuations. Stability is crucial for ensuring that any device powered by this supply will run safely and reliably.

How it’s done:

- Use an electronic load to gradually increase the load from light to heavy and record how the voltage and current respond.

- Introduce sudden load changes (for example, instantly jumping from 0% to 100% load) and see how quickly and accurately the power supply recovers.

What you learn:

If the voltage or current overshoot (go too high) or undershoot (go too low), you’ll know you need to adjust the power supply design to improve its steady output.

2. Dynamic Response and Transient Performance Testing

What it checks:

This test focuses on how fast and well the DC power supply can react to sudden and short-term changes—like a sudden, sharp increase or decrease in load.

Why it’s important:

Many systems experience quick load changes, and the power supply must return to stable operation almost instantly, often within microseconds. A slow or poor response can cause malfunctioning equipment.

How it’s done:

- Quickly switch the load from a low level to a high level using a programmable electronic load.

- Measure how much the voltage dips and how long it takes to recover.

- Simulate real-world events like switches turning on or off, or power grid fluctuations.

What you learn:

If the power supply’s voltage takes too long to recover or fluctuates too widely after a sudden change, you need to improve its transient response capabilities.

3. Ripple and Noise Testing

What it checks:

Ripple and noise refer to small, unwanted fluctuations in the DC output. Too much ripple or noise can interfere with sensitive circuits or cause incorrect readings in control and communication systems.

Why it’s important:

Clean, stable output voltage is essential for equipment performance. Excessive noise can cause errors or damage sensitive electronics.

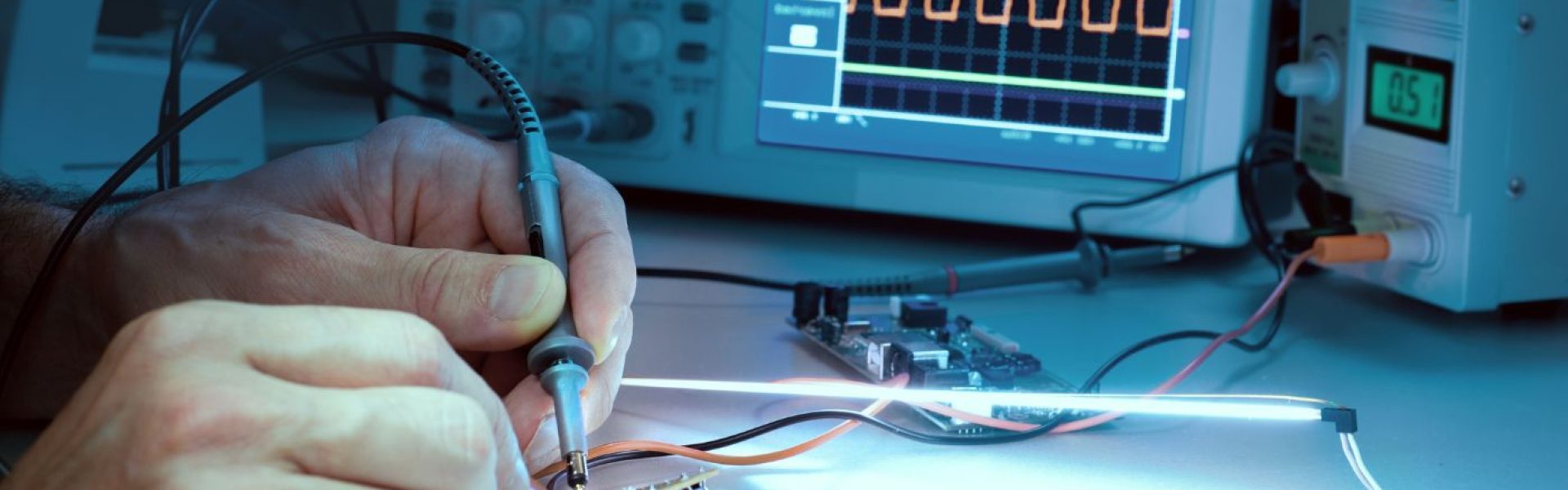

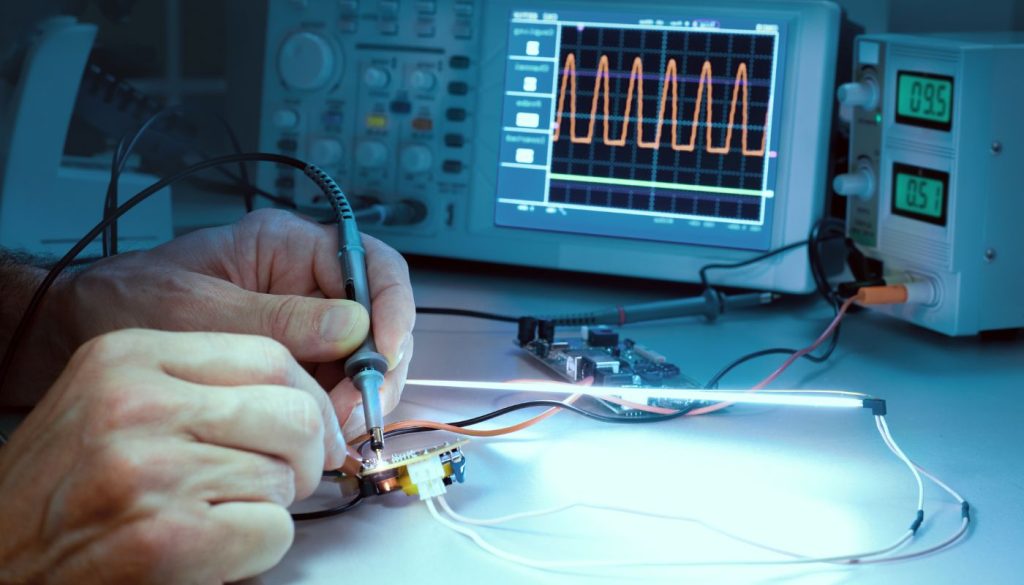

How it’s done:

- Use an oscilloscope with a low-noise probe to measure the small voltage fluctuations at the power supply’s output.

- Analyze the waveform and use frequency analysis (FFT) to identify where the noise is coming from.

- Test under different load conditions and environmental factors (like EMI interference).

What you learn:

If ripple and noise are too high, add or adjust filtering components (such as LC filters or active filters) to clean up the signal.

4. Reliability and Durability Testing

What it checks:

In many environments, the DC power supply must work reliably for long periods under harsh conditions—extreme temperatures, high humidity, vibration, and more.

Why it’s important:

Durability tests confirm that the power supply can maintain stable performance over thousands of hours and under tough conditions. This is crucial for systems used in remote or unmanned locations.

How it’s done:

- Temperature Cycling: Rapidly shift between high and low temperatures.

- Vibration Testing: Shake or vibrate the supply to mimic shipping or harsh on-site conditions.

- Long-Term “Burn-In” Tests: Run the power supply at full load for hundreds of hours and track any performance changes over time.

What you learn:

If the power supply shows output drift, overheating, or other long-term issues, you’ll need to improve its design, cooling, or component quality.

Real-World Examples of DC Power Testing

To understand how these tests apply in practice, consider four example scenarios: a substation control system, a solar power setup, an energy storage system, and an electric vehicle (EV) charging station. Each scenario highlights different testing needs and challenges.

Example 1: Substation Control System

- Situation: A DC power supply in a substation powers protective relays, circuit breakers, and communication devices.

- Key Challenge: Sudden, high current demands occur when switching large breakers on and off.

- Testing Approach: Simulate the breaker operation by creating rapid, high-current load changes. Verify that the DC supply can handle these spikes without voltage overshoot.

- Solution: Improve transient response (e.g., add faster compensation circuits) to prevent any interruptions to the substation’s critical equipment.

Example 2: Solar Power (PV) Systems

- Situation: Solar output changes with sunlight conditions, causing the DC power supply controlling the inverter to face constantly shifting loads.

- Key Challenge: Rapidly adjust to varying input to maintain maximum power point tracking (MPPT) and stable voltage output.

- Testing Approach: Use a programmable DC source and dynamic load to emulate fast sunlight changes. Check how quickly the power supply stabilizes after load variations.

- Solution: Improve the power supply’s control algorithms so it can respond quickly to sunlight fluctuations and maintain efficient inverter operation.

Example 3: Energy Storage Systems

- Situation: Energy storage involves rapid switching between charging and discharging states to stabilize the grid.

- Key Challenge: The DC power supply must handle frequent high-current transitions without losing efficiency or stability.

- Testing Approach: Simulate fast charge/discharge cycles, measure voltage sag and recovery time.

- Solution: Implement “soft-switching” strategies or better control methods to reduce voltage dips and maintain system efficiency.

Example 4: EV Charging Stations

- Situation: Fast-charging EV stations must deliver high current quickly and adapt to different EV battery requirements. Multiple charging ports may be active at once.

- Key Challenge: The DC power supply must handle large, sudden load changes as EVs connect and disconnect, and share power among multiple stations.

- Testing Approach: Use multi-channel loads to simulate various vehicles charging at once. Measure voltage stability and power distribution accuracy under dynamic conditions.

- Solution: Introduce intelligent load forecasting and dynamic power distribution control so that each charging point gets stable voltage even at high loads.

Future Trends in DC Power Testing

- Higher Efficiency and Power Density:

Test equipment will become smaller, more powerful, and more energy-efficient, helping manage large-scale, high-power applications. - Intelligent and Automated Testing:

Expect more integration with AI and automation. Future testing systems will recognize testing patterns, adjust parameters automatically, and quickly identify issues, reducing human error and speeding up the entire process. - Integrated, Multi-Function Testing Platforms:

Future testers will combine multiple test functions—like dynamic response, reliability, and EMI testing—into a single platform. This all-in-one approach simplifies the testing process and prepares engineers for more complex systems.

Conclusion

DC power supplies are critical components in modern power systems—from controlling substation equipment to supporting solar plants, energy storage, and EV charging. Robust testing ensures these supplies deliver stable, clean, and reliable power under various conditions. By thoroughly checking voltage/current stability, transient response, ripple/noise, and long-term durability, engineers can significantly improve the overall safety and reliability of power systems.

As power systems and new energy technologies grow more complex, DC power testing will continue moving toward smarter, more automated, and more integrated solutions. By investing in advanced testing methods, equipment, and strategies, companies can stay ahead of industry changes, meet strict standards, and ensure their products perform at the highest level.

Choose Infinipower’s DC power testing solutions for comprehensive performance assurance. Our advanced equipment and industry expertise can help you tackle challenges in substations, solar plants, energy storage, and EV charging. By integrating our efficient testing processes into your design and production stages, you can deliver the most reliable and top-quality solutions to your customers.

Contact our technical team today to learn how precise DC power testing can enhance your products, giving you a competitive edge in the rapidly evolving energy market.